The Single Strategy To Use For Motor Control Induction Motor AC - Newark

AC Motors - Asynchronous for Beginners

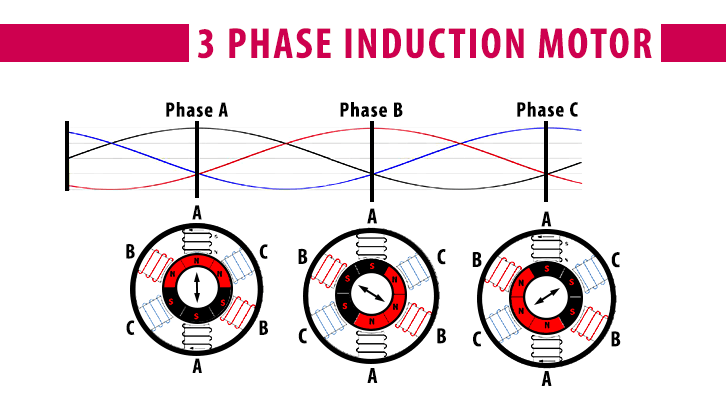

Self-starting polyphase induction motors produce torque even at grinding halt. Available squirrel-cage induction motor starting techniques include direct-on-line beginning, reduced-voltage reactor or auto-transformer starting, star-delta beginning or, significantly, brand-new solid-state soft assemblies and, obviously, variable frequency drives (VFDs). Polyphase motors have rotor bars formed to give various speed-torque qualities. The present circulation within the rotor bars differs depending on the frequency of the caused current.

The different bar shapes can provide usefully various speed-torque qualities along with some control over the inrush current at start-up. Although polyphase motors are naturally self-starting, their starting and pull-up torque style limitations need to be high sufficient to conquer real load conditions. In wound rotor motors, rotor circuit connection through slip rings to external resistances allows modification of speed-torque attributes for acceleration control and speed control purposes.

On/off Electric Motor Control Circuits - Discrete Control System Elements - Automation Textbook

Low-Noise Induction Motor IK Type-K Series - Luyang, Outstanding AC Induction Motor Manufacturers

The 7-Minute Rule for Induction VsPermanent Magnet Motor Efficiency - Horizon

Applications such as electric overhead cranes used DC drives or wound rotor motors (WRIM) with slip rings for rotor circuit connection to variable external resistance enabling significant series of speed control. However, resistor losses associated with low speed operation of WRIMs is a significant cost disadvantage, especially for constant loads.

The speed of a pair of slip-ring motors can be managed by a cascade connection, or concatenation. The rotor of one motor is linked to the stator of the other. If Related Source Here are also mechanically connected, they will run at half speed. This system was when widely used in three-phase A/C train locomotives, such as FS Class E. 333.

Fascination About How AC induction motors work - Woodgears.ca

The most typical efficient method to manage asynchronous motor speed of lots of loads is with VFDs. Barriers to adoption of VFDs due to cost and reliability factors to consider have been decreased considerably over the previous three decades such that it is approximated that drive technology is embraced in as numerous as 3040% of all newly set up motors.

Induction motor - Wikipedia

With scalar control, just the magnitude and frequency of the supply voltage are managed without phase control (absent feedback by rotor position). Scalar control appropriates for application where the load is constant. Vector control enables independent control of the speed and torque of the motor, making it possible to preserve a continuous rotation speed at differing load torque.